Table of Contents

Introduction

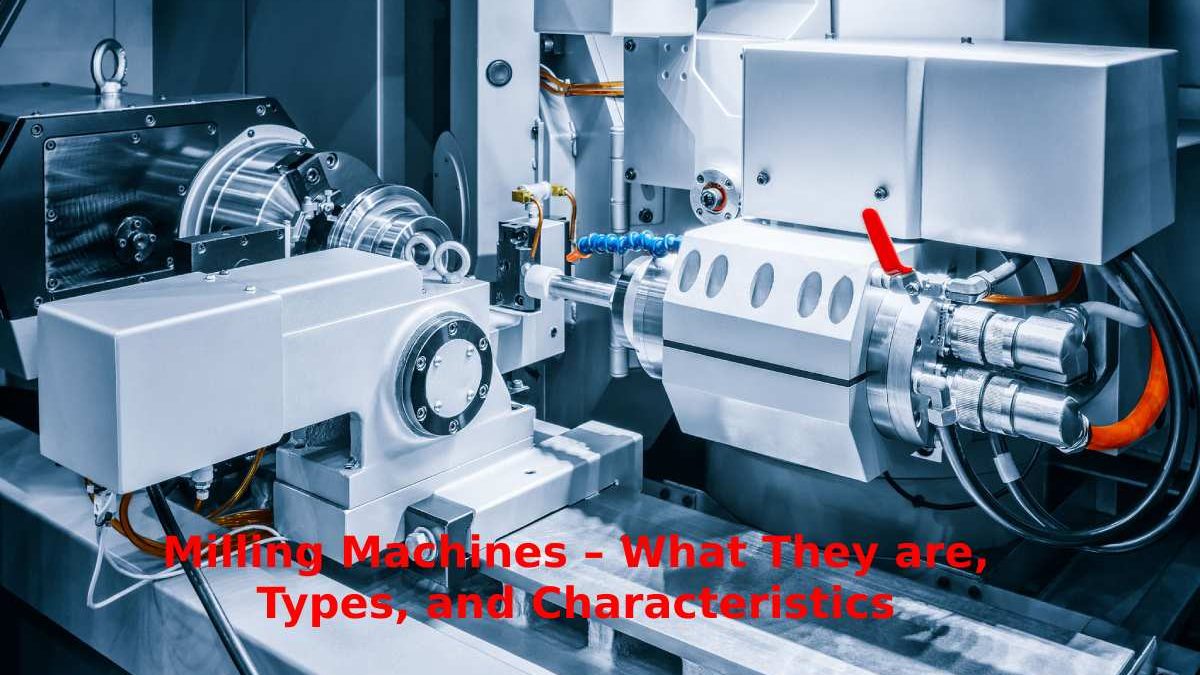

The milling machines are one of fascinating tools for manufacturing and machining enthusiasts. In this article, we will talk about what milling machines are, what types there are, what they are used for, and also what kinds of parts and operations can be performed with one of them.

What is it Used for?

A milling machine is a machine that outlines, cuts, or (even) drills various solid materials, usually metal. It is done by removing chips by high-speed rotation of the cutting tool and movement of the element or mechanism shaft. This type of part manufacturing technology by chip removal is called machining.

The milling cutter remains the cutting tool used in milling machines. A blade contains one or more chip flutes, and also the cutting edges shed metal chips as the device rotates.

Also Read: Digital Branding – Introduction, Importance, Strategy, and More

Parts of a Milling Machine

Now that we know its functions let’s discover the anatomy of a milling machine. But first, it is essential to remember. For this reason, we cite the most important ones.

Table

We will place the part that we need to trim there. Next, the raw metal block to be mill is fix on the table with different systems. The most common method is to clamp the workpiece in a vise or with clamps, bolts, and nuts, as the workpiece must be secure firmly and in the correct position before milling can begin.

Cranks

They are the ones that give movement to the Cartesian axes. There is an “X,” a “Y,” and a “Z.” With them, we move the part attached to the bed and the spindle, which contains the cutter. You can have several of these elements depending on the number of functional movements of the machine or if we place the fourth axis of rotation.

Also Read: What is Ethereum? – Its work and More

Head

On it is the device that holds and holds the cutting element. Sometimes, it may contain the ignition switch and accessories such as lamps and coolant hoses. And it includes the axis of the tool or the spindle, the element that rotates, and also on which the cutter is place for cutting.

Engine

Another essential part of a milling machine. It is the heart of the device. Horsepower, speed, and also torque vary by model and application. There are variable speed motors that operate electronically and fixed speed motors that regulate speed and power with a system of pulleys or gears.

Transmission

Not all materials or all metals are cut at the same speed. Each combination of material and material to be cut requires a different RPM of the tool to achieve the best possible finish and also ensure tool life is not compromise.

Also Read: Best Meeting Pods for your Flex Office

Types of Milling Machines

Vertical Milling Machines

In these types of milling machines, the spindle’s axis is perpendicular to the table. Allows vertical movement of the tool.

Horizontal Milling Machines

In these milling machines, the spindle is “lying down” and also moves horizontally concerning the table.

Universal Horizontal Milling Machine

These milling machines differ from common horizontal ones as they have a table capable of moving up to 45 degrees and also tilting the part.

CNC Milling Machines

They are milling machines with the latest technology. For example, they have a computerized numerical control that automates the milling machine’s movements so that they do not depend on a person, making them faster and more precise.

Also Read: Technology – All About 5G Technology

Conclusion

A milling machine is a machine tool for machining work by chip removal through the movement of a rotary tool with several cutting edges, called a milling cutter.

Also Read: What is Robotics and what is it For?